https://www.wardsauto.com/automakers/meeting-automotive-electronics-needs-with-henkel-s-next-gen-gap-fillers

BERGQUIST Gap Filler TGF 4400LVO is helping to meet performance and production needs through solutions tailored for demanding automotive applications

October 29, 2024

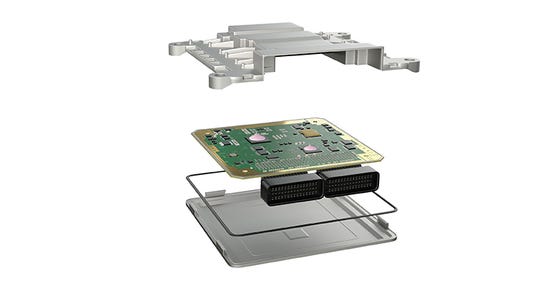

As vehicles become increasingly connected and driving is transformed by sophisticated ADAS and autonomous driving technologies, key trends are impacting the need for more efficient thermal management across automotive electronic components, including:

- Miniaturization – smaller component sizes leave less space for use as a heat sink

- Systems integration – increased functionality in one system

- Powerful processing and functionalities – more heat is generated as processing power increases

In addition to meeting reliability and safety standards, OEMs and component suppliers must also meet requirements for high production demand and improved sustainability, while ensuring high performance.

Henkel’s next generation of thermal gap fillers is helping to meet these needs through solutions tailored specifically for demanding automotive applications. BERGQUIST Gap Filler TGF 4400LVO, first in a series of products that will address these evolving requirements, is a 2-component, room temperature cure filler based on low-volatile silicone technology.

This fast-dispensing gap filler, with a typical thermal conductivity of 4.4 W/mK, enables high reliability under severe thermal load and is ideal for demanding automotive applications, such as automotive control units, ADAS camera, LiDAR data module and displays.

Product Performance

With a thin bond-line thickness of ~90-110 µm and excellent wet-out, 4400LVO reduces thermal resistivity, while delivering high adhesive strength. In addition to its high heat transfer capability, the product delivers good dielectric strength, offering improved insulation for higher voltage applications. Over time, Henkel’s next generation gap filler solution demonstrates good thermal performance and dielectric strength even when subjected to a thermal shock scenario where temperatures changed rapidly from -40C to +125C.

Meeting High Production Demand & Process Flexibility

Meeting High Production Demand & Process Flexibility

The rheological properties of material solutions determine the ease of application, assembly and final product performance. Henkel’s BERGQUIST Gap Filler TGF4400LVO is formulated for fast and robust dispensing, with high shot consistency for high throughput manufacturing. In addition to fast dispense time, TGF4400LVO provides a working time of more than 90 minutes, enabling a wider process window. The product cures within 12 hours at room temperature – but can be accelerated with heat.

Improving Sustainability

Improving Sustainability

The long working time of Henkel’s BERGQUIST Gap Filler TGF 4400LVO increases production flexibility, while reducing scrap. Additionally, Henkel’s next generation gap filler series eliminates the use of Siloxanes D4-D5-D6, meeting REACH standards, while making the solutions suitable for silicone-sensitive applications.

BERGQUIST GAP FILLER TGF 4400LVO PRODUCT PROPERTIES

| TECHNOLOGY | SILICONE (2 C) |

|---|---|

| Thermal Conductivity, ASTM D5470 | 4.4 W/(m.K) typical |

| Shore Hardness (00) | 90 |

| Flow Rate (EFD 30 cc, 90 psi) | Part A: 1.0 cc/sec; Part B: 1.2 cc/sec |

| Cure | Room temperature or heat |

| Working Time | 90 min at 25 C |